…is not a place to store mud. When we first bought the cottage in December, Emily was all about the idea of having a mudroom. “If we’re going to be farming, we’re going to need a place to take off our shoes.” Yeah, i guess that makes sense. I didn’t like the idea of making the house bigger, bur ironically, adding the space allows us to keep the house small by containing the mess.

…is not a place to store mud. When we first bought the cottage in December, Emily was all about the idea of having a mudroom. “If we’re going to be farming, we’re going to need a place to take off our shoes.” Yeah, i guess that makes sense. I didn’t like the idea of making the house bigger, bur ironically, adding the space allows us to keep the house small by containing the mess.

The first step to making a mudroom is to dig in mud. This turned out to be a lot less work than I was expecting, for several reasons: A) the soil is fairly easy to cut, being forest duff with relatively low clay percentage; B) I didn’t have to dig down very far, because the frost depth here is a scant 12″; and C) I was using a Guatemala-style hoe. I dug the whole thing in a short day.

The first step to making a mudroom is to dig in mud. This turned out to be a lot less work than I was expecting, for several reasons: A) the soil is fairly easy to cut, being forest duff with relatively low clay percentage; B) I didn’t have to dig down very far, because the frost depth here is a scant 12″; and C) I was using a Guatemala-style hoe. I dug the whole thing in a short day.

Now we install rebar. This is something I got pretty good at while making water tanks in the Peace Corps. The only difference is that to bend the rebar, I had to use a big machine at the hardware store, because no one in this country sells (or has even heard of) grifas. Rebar bending by hand will soon go the way of the lost art of Japanese swordmaking.

Now we install rebar. This is something I got pretty good at while making water tanks in the Peace Corps. The only difference is that to bend the rebar, I had to use a big machine at the hardware store, because no one in this country sells (or has even heard of) grifas. Rebar bending by hand will soon go the way of the lost art of Japanese swordmaking.

The next step was to form it up for concrete. David, an architect buddy of mine, had some monoform supports lying around his house so he donated them to the project. I’ve never formed a concrete wall this way before, but it’s convenient: you make the form for the spread footing, lay the steel supports over it, and drop plywood panels into the clips on the supports. The supports are left behind permanently in the wall, and you don’t have to do two separate pours for footing and foundation wall. This is awesome, because…

The next step was to form it up for concrete. David, an architect buddy of mine, had some monoform supports lying around his house so he donated them to the project. I’ve never formed a concrete wall this way before, but it’s convenient: you make the form for the spread footing, lay the steel supports over it, and drop plywood panels into the clips on the supports. The supports are left behind permanently in the wall, and you don’t have to do two separate pours for footing and foundation wall. This is awesome, because…

I have to pump concrete uphill! Our house is about 12 feet above and 30 feet away from the closest place the concrete truck can reach, so I have to also pay a concrete pump guy $350 per visit to help me. So, doing this in one shot saves big money. The concrete pump is pretty cool, and is just what it sounds like: I giant pump with a 4″ hose that poops out liquid rock. As Emily will attest, concrete day is pretty stressful: you have to get everything ready beforehand, not forget anything (like the various embedded anchors), and you have only one shot at getting it right. The good news? It has a finite end to the stress, because by the time an hour has gone by after the truck arrives, you’re done whether you want to be or not! (the concrete is set)

I have to pump concrete uphill! Our house is about 12 feet above and 30 feet away from the closest place the concrete truck can reach, so I have to also pay a concrete pump guy $350 per visit to help me. So, doing this in one shot saves big money. The concrete pump is pretty cool, and is just what it sounds like: I giant pump with a 4″ hose that poops out liquid rock. As Emily will attest, concrete day is pretty stressful: you have to get everything ready beforehand, not forget anything (like the various embedded anchors), and you have only one shot at getting it right. The good news? It has a finite end to the stress, because by the time an hour has gone by after the truck arrives, you’re done whether you want to be or not! (the concrete is set)

After that, it’s waiting 7 days for it to reach first strength.

After that, it’s waiting 7 days for it to reach first strength.

We had some friends who were eager to help work on the house, so we took that opportunity to match them up with a project that could benefit from some extra manpower, as well as be satisfying for them (and make it more likely they would return again!). They got right to work, starting out with stripping the forms, then cut the bolt holes in the treated mudsills and installed them.

While they were doing that, I called upon Ryan to use his elite woodworking skillz to help me make mortises for the heavy cedar beams that will hold up the awning over the front door. I decided to make it a really deep awning, to better protect from the incessant rain in this climate. Luckily, the incessant rain also grows awesome trees. You can get some wood in these parts that was definitely not available in the midwest- that thing Ryan is carving out is a cedar 6×10. Heh.

While they were doing that, I called upon Ryan to use his elite woodworking skillz to help me make mortises for the heavy cedar beams that will hold up the awning over the front door. I decided to make it a really deep awning, to better protect from the incessant rain in this climate. Luckily, the incessant rain also grows awesome trees. You can get some wood in these parts that was definitely not available in the midwest- that thing Ryan is carving out is a cedar 6×10. Heh.

By the time I got back, they were ready for the platform, so I showed them how to do that and they got right to business. Here’s Lindsey and Allyson screwing down the subfloor. Once that’s taken care of, it’s on to making the walls. We built them on the platform, then lifted them up into place. About the time that happened, the cedar beams were ready, so we got everyone together and lifted them onto the walls.

By the time I got back, they were ready for the platform, so I showed them how to do that and they got right to business. Here’s Lindsey and Allyson screwing down the subfloor. Once that’s taken care of, it’s on to making the walls. We built them on the platform, then lifted them up into place. About the time that happened, the cedar beams were ready, so we got everyone together and lifted them onto the walls.

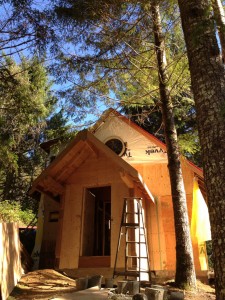

This is a good time to point out that they are WAY oversized… I wanted to use cedar, because I am going to leave them exposed to the elements and cedar is naturally rot resistant. And cedar is weaker than Douglas fir, so it would need to be a little bigger, but in this case they are much more massive than necessary to make the structure look “right” proportionally. Kindof feels like an Amish barnraising in this picture, huh?

This is a good time to point out that they are WAY oversized… I wanted to use cedar, because I am going to leave them exposed to the elements and cedar is naturally rot resistant. And cedar is weaker than Douglas fir, so it would need to be a little bigger, but in this case they are much more massive than necessary to make the structure look “right” proportionally. Kindof feels like an Amish barnraising in this picture, huh?

Once the walls were up, the weekend was prettymuch over and our work crew had to return to their normal lives. But not me! After working my “day job” the next morning, I was back out that afternoon, putting in rafters. The entire mudroom is only 8′ wide, but I’m using 2×12 rafters to give me enough rom to get the full R32 insulation in there for superextra awesome warmity.

Once the walls were up, the weekend was prettymuch over and our work crew had to return to their normal lives. But not me! After working my “day job” the next morning, I was back out that afternoon, putting in rafters. The entire mudroom is only 8′ wide, but I’m using 2×12 rafters to give me enough rom to get the full R32 insulation in there for superextra awesome warmity.

We’re nearly there! On top of the rafters goes the 1/2″ plywood, and then the synthetic roof underlayment. It used to be that 15# asphalt paper did that job, but newer technology prevails. After trying it, I’m hooked: it is lighter and easier to handle, not messy, covers more per roll, and has a nonslip surface. Also, if you use the recommended (goofy) 1″ plastic headed nails, you are warranted for 180 days exposure and 90mph wind. Now all that’s left is the roof itself, which will be the subject of an upcoming post.

We’re nearly there! On top of the rafters goes the 1/2″ plywood, and then the synthetic roof underlayment. It used to be that 15# asphalt paper did that job, but newer technology prevails. After trying it, I’m hooked: it is lighter and easier to handle, not messy, covers more per roll, and has a nonslip surface. Also, if you use the recommended (goofy) 1″ plastic headed nails, you are warranted for 180 days exposure and 90mph wind. Now all that’s left is the roof itself, which will be the subject of an upcoming post.